Maximizing Efficiency: Selecting the Right Aftermarket Construction Parts for Your Fleet

Maximizing Efficiency: Selecting the Right Aftermarket Construction Parts for Your Fleet

Blog Article

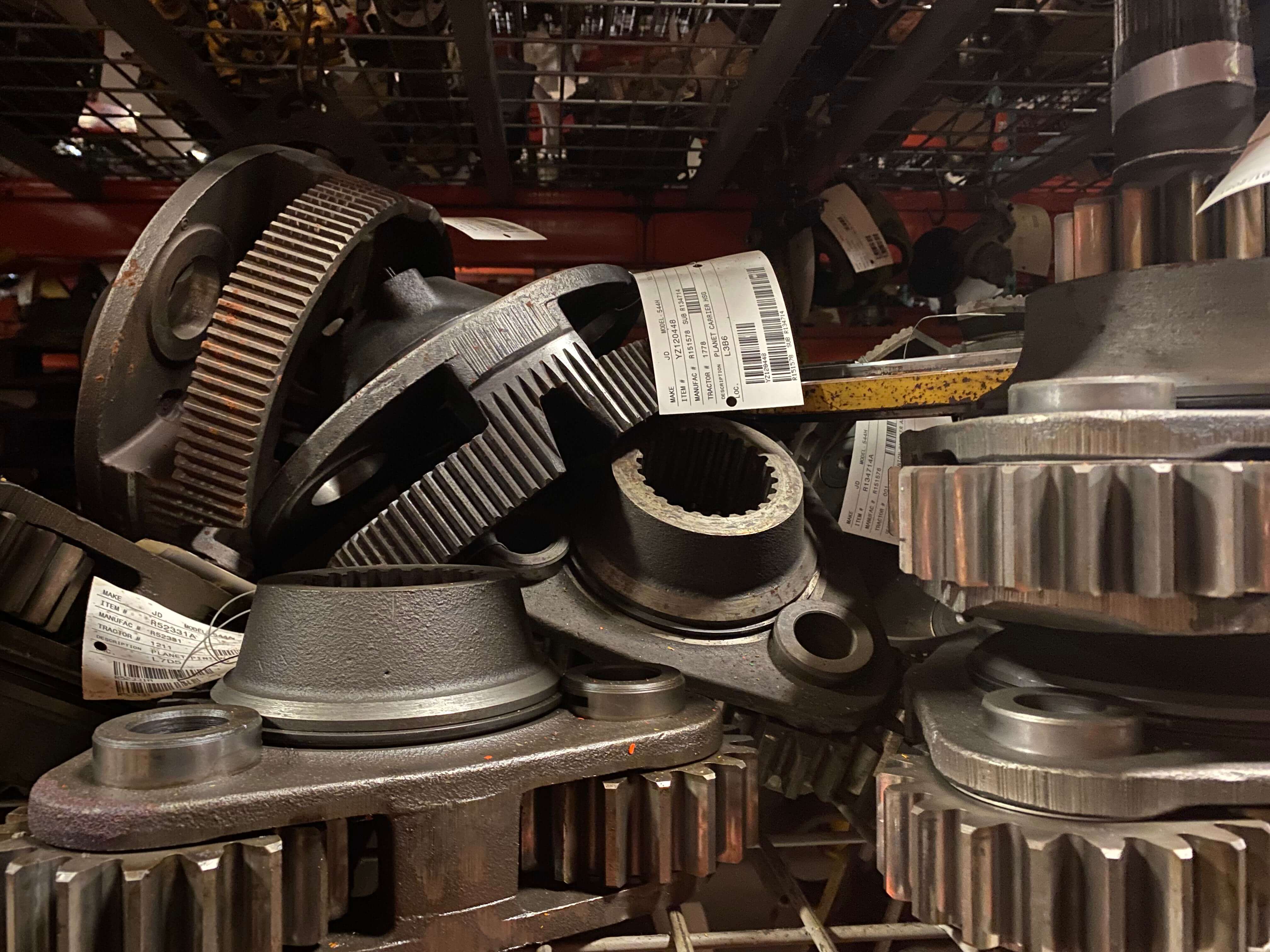

Increase Effectiveness With Aftermarket Components: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Components

Owners of hefty machinery can delight in numerous advantages by selecting aftermarket components over initial tools manufacturer (OEM) parts. Among the key benefits is cost savings. Aftermarket parts are commonly more economical than OEM components, permitting equipment proprietors to lower upkeep and repair costs without compromising on quality. Additionally, aftermarket parts commonly feature service warranties, ensuring that buyers are protected in case of any issues or issues.

An additional benefit of aftermarket parts is the bigger option offered out there. Because aftermarket manufacturers concentrate on creating particular components, equipment owners have accessibility to a wider variety of alternatives to match their requirements. This variety can lead to improved performance and performance of the machinery. Furthermore, aftermarket components are understood for their quality and dependability, with many conference or surpassing OEM criteria.

Last but not least, choosing aftermarket parts can additionally cause faster repair work and lowered downtime. With easier accessibility and fast shipping choices, equipment owners can get their tools up and running once more swiftly, lessening disturbances to their operations.

Selecting the Right Aftermarket Components

When considering aftermarket components for heavy equipment, it is vital to prioritize compatibility and high quality to guarantee ideal efficiency and durability of the devices. Picking the appropriate aftermarket components can be a crucial decision for heavy machinery owners as it directly influences the effectiveness and dependability of their devices.

Secondly, quality should never be compromised when choosing aftermarket parts (aftermarket construction parts). Choosing top quality components ensures sturdiness, dependability, and general performance of the machinery. It is advisable to resource aftermarket components from reputable manufacturers or suppliers known for their quality criteria

Additionally, considering factors such as warranties, consumer testimonials, and compatibility with existing systems can additionally help in making the best choice. By prioritizing compatibility and top quality when picking aftermarket components, heavy machinery owners can boost the performance and long life of their devices.

Setup and Maintenance Tips

For efficient operation and longevity of heavy machinery, proper installation and regular maintenance are critical. When setting up aftermarket parts, guarantee that you meticulously follow the manufacturer's instructions to guarantee optimum efficiency. By focusing on installment and upkeep procedures, you can optimize the performance and life-span of your hefty machinery, ultimately saving time and money in the lengthy run.

Cost-Effectiveness of Aftermarket Components

Correct installation and regular maintenance are fundamental aspects for heavy machinery owners aiming to examine the cost-effectiveness of aftermarket components for their tools. While original equipment producer (OEM) parts are understood useful reference for their high quality, aftermarket components use an even more cost-efficient solution without compromising performance. By carefully assessing the top quality and compatibility of aftermarket components with their equipment, proprietors can strike an equilibrium in between cost-effectiveness and performance, eventually maximizing the effectiveness and durability of their hefty tools.

Maximizing Effectiveness With Aftermarket Upgrades

To improve operational performance and performance, hefty machinery proprietors can efficiently optimize efficiency through strategic usage of aftermarket upgrades. Aftermarket upgrades provide the chance to tailor heavy machinery to details operational needs, causing enhanced performance and outcome. Upgrading elements such as engines, transmissions, hydraulic systems, and tracks can substantially improve the general efficiency of the equipment.

On a regular basis assessing the efficiency of hefty machinery and identifying locations where aftermarket upgrades can be advantageous is crucial look at these guys for making best use of performance. By buying top quality aftermarket components and upgrades, equipment owners can accomplish greater degrees of efficiency, eventually causing set you back savings and enhanced functional outcomes.

Final Thought

In verdict, aftermarket components offer many advantages for hefty machinery owners, including cost-effectiveness, raised efficiency, and personalization alternatives. By picking the right aftermarket parts, following appropriate setup and upkeep treatments, and making the most of upgrades, heavy machinery owners can improve their tools's efficiency and longevity. Investing in aftermarket parts can eventually bring about improved productivity and minimized downtime, making it a worthwhile factor to consider for owners seeking to maximize their equipment procedures.

Owners of heavy equipment can enjoy various advantages by deciding for aftermarket parts over initial equipment supplier (OEM) parts. Aftermarket parts are commonly a lot more affordable than OEM parts, permitting machinery proprietors to minimize maintenance and repair prices without endangering on high quality. By carefully reviewing the quality and compatibility of aftermarket parts with their equipment, owners can strike an equilibrium in between cost-effectiveness and efficiency, ultimately making best use of the efficiency and durability of their heavy devices.

In conclusion, aftermarket components supply many advantages for heavy machinery proprietors, consisting of cost-effectiveness, raised performance, and customization options. By picking the appropriate aftermarket components, following proper installment and maintenance treatments, and maximizing upgrades, hefty machinery proprietors can boost their read here tools's performance and long life.

Report this page